CNC Turning

At Roosen Industries we have our turning expertise on a lot of different materials. Steel, stainless steel, aluminum and brass are materials which we turn on a regular base however also a lot of plastics are easy to machine on our equipment.

We have 2 production companies with CNC-controlled machines. One factory in Europe and one factory in Asia. In the Netherlands we have automated the machinery and we operate with an automatic loading and unloading of both the raw material and final machined product. In Asia we have a comparable machine park where your product price can be calculated on even a more attractive price level caused by the low local cost price structure. Both locations have a conditioned measuring room with 3D measuring machines, which controls a high level of quality of the final product.

If your turned parts require any surface treatment, we will work with one of our external partners to realise this for you.

We unburden you from any logistical activities throughout the entire process in producing your product!

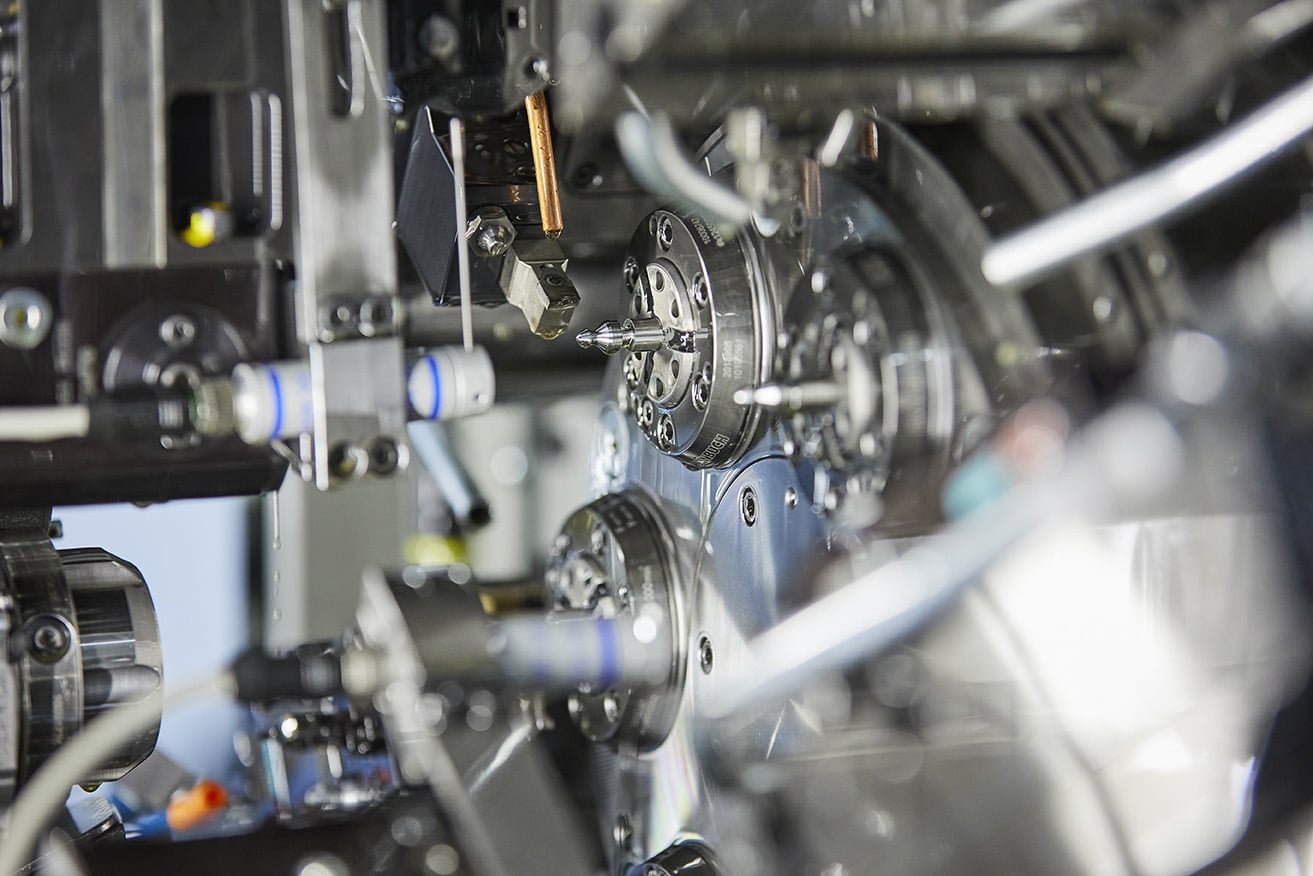

Robotised CNC turning in Europe

In Europe we are fully focused on automating our production processes. Our lathes, turning and milling combinations are (where possible) equipped with cobots: robots or other automatic loading and unloading devices for your products. To ensure 24/7 unmanned production we are training our operators on a regular basis to maintain a high level of product quality for our customers.

CNC turning Asia

Roosen started in 2006 with it’s own machining factory in India having similar machines installed as we have in our Dutch factory. A well educated population and masters in the English language, combined with a low cost structure were key figures for the strategic decision to start in India.

We are located in Kanpur, where the local universities provide us with the necessary support and provide sufficient staff to continue with a 3 shifts production. In 2023 we had the grand opening of our new Indian factory which is completely built according to European standards. A fully air-conditioned building and of course an air-conditioned measuring room including 3D measuring equipment.

Is production in India right for your business as well? We are pleased to guide and advise you what to do. One of the essential requirements is to receive your forecast on your products. Starting up a first production batch takes a longer lead time, but based on your forecast we can then guarantee your supply chain with monthly deliveries. (Vigil-Whistle Blower Mechanism).

Whichever Roosen company you work with, the communication for you as a customer, also for India production, always goes through 1 and the same Dutch Roosen account manager.

Serial production

NPI (New Product Introduction) is a special procedure within Roosen since every product starts with a prototype or pre-series. In the next step we will focus on an optimised serie production for products with a repeatable character. Lot sizes vary from 10 pieces to thousand(s) products per month. The repeatable character is essential to create a continuous flow on our shop floor and to ensure short and reliable processing times for your products.

Cleaning and packaging

Interested in cleaning and packaging your machined products in our clean room ? For this activity you can contact Roosen Industries.